Automation Engineering

Kim Control Systems will design, program, simulate and test a comprehensive system to automate your processes. That can include data reporting designed to optimize your product or production system, a process control system and programming for control and feedback. Since 1971 we have worked with companies in many industries including:

• Manufacturing

• Medical

• Power Transmission

• Safety

• Precision Motion

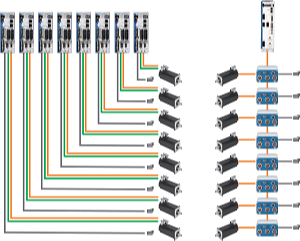

Motion Control Systems

Design, engineering and manufacturing of the complete control system including mechanical components like motors, gears, actuators, conveyors all controlled by a processor with feedback systems. Kim Control Systems has the parts, programming capability and mechanical knowledge to design, select, and build your motion control system.

• Production Lines

• Production Machinery

• CNC and Cutting Machines

• Machine Safety System

• Precision Motion

Manufacturing

Electrical products:

• UL 508A , cUL Control Panels

• Power Distribution Panels

• HMI Enclosures and Flexible Arms

• Custom Wiring

Mechanical Products:

• Work Benches & Cells

• Machine Enclosures

• Production Lines

• Safety Fences & Screens

• Conveyors

• Custom Actuators

• Staircase & Mezzanines

• Employee safety screens